In the modern kitchen, sustainability usually focuses on ingredients—sourcing local produce, reducing food waste, or composting scraps. However, the tools we use to prepare that food are just as critical to our environmental footprint. Restoring and reusing vintage Japanese knives is more than an appreciation of craftsmanship; it is a direct act of reducing waste, preserving history, and making a responsible choice for the planet.

Here is how choosing a restored blade from the Past Knife Catalog helps the environment while delivering exceptional culinary performance.

1. The Hidden Waste of Modern Knife Production

While mass production has made kitchen tools more accessible, it has come at a significant environmental cost. The lifecycle of a cheap, factory-made knife is often short, leading to a cycle of consumption and disposal that taxes the planet’s resources.

Why New Knife Manufacturing Creates Waste

- Excessive Mining: Extracting raw materials like iron ore and chromium contributes to deforestation, soil erosion, and ecosystem disruption.

- High Energy Consumption: The smelting and forging processes for new steel require massive amounts of electricity and fossil fuels, contributing heavily to greenhouse gas emissions.

- The Landfill Problem: Inexpensive, low-quality knives are rarely designed for maintenance. When they dull or chip, they are often discarded rather than sharpened, contributing to landfill overflow.

Fact: Over 300 million kitchen knives are produced globally each year, with a significant portion ending up as waste within just a few years of purchase.

2. Why Restoring Knives Is the Eco-Friendly Choice

Choosing a restored vintage knife significantly reduces your kitchen’s environmental footprint. It is a form of upcycling that prioritizes quality over quantity.

- Reduces Material Waste: Restoring a vintage blade requires no additional raw steel, preventing further mining damage and raw material processing.

- Lowers Carbon Emissions: The energy required to clean, sharpen, and re-handle an existing blade is a fraction of what is needed to manufacture, package, and ship a new one from a factory.

- Extends Product Lifespan: A well-made Japanese knife, when properly restored, can last another 20 to 50 years. This longevity drastically reduces the demand for disposable alternatives.

Many traditional Japanese knives were forged using higher-quality carbon steel than modern mass-produced equivalents. By saving these blades, you are preserving superior materials that would otherwise be lost.

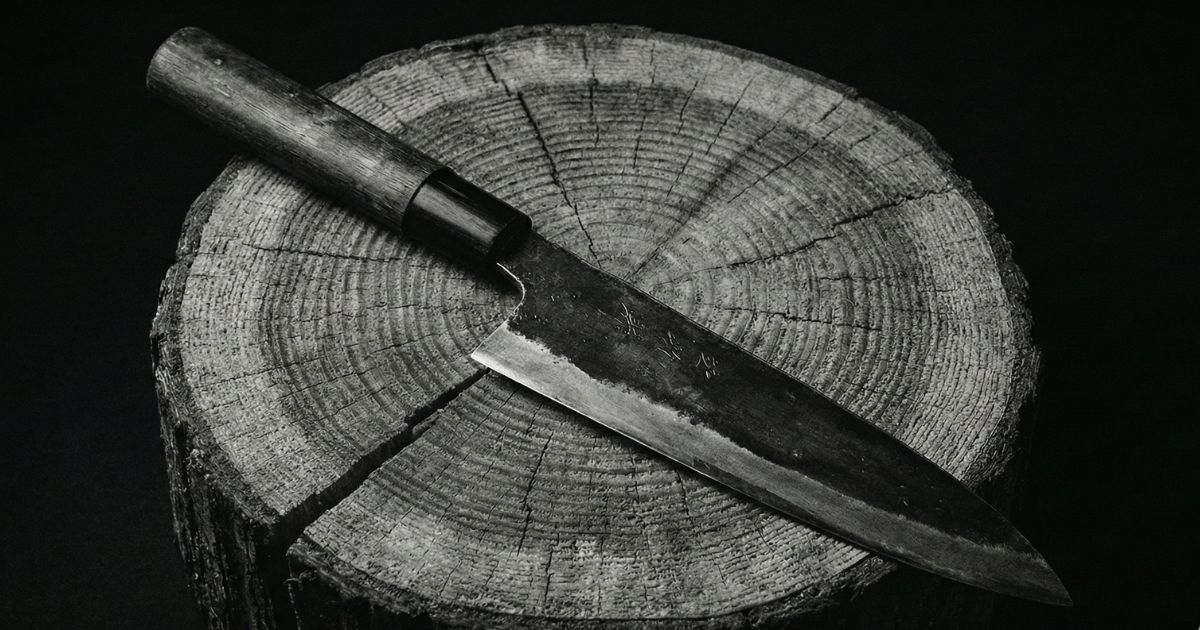

3. The Art of Preservation

Restoration is not simply about making an old knife look new; it is about honoring its history while enhancing its utility. You can read more about the stories behind vintage Japanese knives to understand why these specific tools are worth saving.

The Knife Restoration Process

- Blade Refinishing: Rust, deep stains, and pitting are carefully removed while preserving the original geometry and “distal taper” of the blade.

- Sharpening and Honing: The edge is brought back to razor-sharp precision using traditional whetstone techniques, often exceeding the sharpness of new factory knives.

- Handle Repair or Replacement: Damaged handles are repaired or replaced with traditional woods like magnolia, yew, or rosewood, which are sustainable and biodegradable.

- Final Polishing and Protection: A light application of camellia oil seals the steel against moisture.

Pro Tip: Vintage Japanese knives often develop a distinct patina over time. This natural oxidation is not a defect; it acts as a protective layer for the carbon steel and gives the knife unique character.

4. The Carbon Footprint: New vs. Restored

When comparing a restored vintage knife to a newly manufactured one, the difference in environmental impact is stark.

| Factor | New Factory Knife | Restored Vintage Knife |

| Raw Materials | High (Requires mining and refining) | None (Existing steel is repurposed) |

| Energy Use | High (Smelting, forging, global shipping) | Low (Manual labor, local restoration) |

| Waste Generated | Moderate to High (Packaging, industrial byproduct) | Minimal to None |

| Lifespan | 5–15 years (Average) | 20–50+ years (With care) |

Impact: Choosing a restored knife can cut the carbon footprint associated with that purchase by over 80% compared to buying new.

5. The Beauty of Owning a Restored Knife

Beyond sustainability, restored knives offer a level of character and craftsmanship that is rare in today’s market.

- Hand-Forged Quality: Many vintage Japanese knives were created by master blacksmiths using techniques passed down for centuries, resulting in superior grain structure and cutting ability.

- Personal History: Every scratch, stamp, and curve on a restored blade tells a story, connecting you to the artisans who forged it and the chefs who used it.

- Superior Steel: Older high-carbon Japanese steels (such as Shirogami or Aogami) often outperform modern stainless steel blends regarding ease of sharpening and edge retention.

Insight: Some restored Japanese knives currently in circulation are over 100 years old and still function with more precision than brand-new commercial blades.

6. How to Care for a Restored Japanese Knife

Sustainability requires maintenance. To ensure your restored knife lasts for generations, follow these simple care guidelines:

- Hand Wash Only: Never place a vintage knife in a dishwasher. The heat and harsh detergents will damage the handle and rust the blade.

- Dry Immediately: High-carbon steel is reactive. Wipe the blade dry immediately after washing to prevent red rust.

- Use the Right Cutting Board: Use soft wooden or rubber cutting boards to maintain the edge; avoid glass, granite, or hard plastic.

- Oil Periodically: A thin layer of food-safe oil (such as camellia or mineral oil) creates a barrier against moisture when the knife is stored.

A Knife with a Past, A Future for the Planet

Buying a restored Japanese knife is a statement against the throwaway culture of modern consumerism. It is an investment in craftsmanship, tradition, and environmental responsibility. Choosing restoration over new manufacturing reduces waste, conserves resources, and grants you access to a level of cutting performance that is disappearing from the modern world.

At Past Knife, we take pride in bringing these exceptional tools back to life. Explore our catalog to discover the beauty, history, and sustainability of a restored knife—because a great blade should last more than a lifetime.